Modern warehouses need to maximise vertical storage space. Hence they need an upgrade over manual stackers which limit the load capacity and lift height. Battery operated stackers revolutionise pallet handling providing a zero effort solution to the challenges faced by operators while using the manual alternatives.

The battery operated stackers offered by Avcon Systems are an even better upgrade over generic electric stackers offered by other material handling manufacturers. These speed up pallet movement without compromising operator comfort and safety.

In this blog, we understand how choosing the right battery operated electric stacker can streamline pallet handling in your warehouse operations and why Avcon’s battery operated fully electric stackers stand out.

What are battery operated stackers?

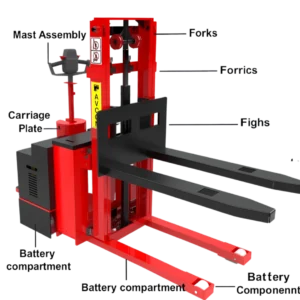

A battery operated stacker is a pallet handling equipment used in warehouses where there is frequent loading and unloading of high volume palletised loads. Powered by a rechargeable battery these fully automatic stackers lift, lower and drive electrically allowing a single operator to move heavy pallets in tight aisles easily.

Avcon Systems offers battery operated stackers tailored to your warehouse needs and specifications. Our battery operated stackers are available in counterbalanced, straddle form and semi electric models.

What are the applications of battery operated stackers?

Avcon’s battery operated stackers simplify workflows in those places that require speed, safety, and efficiency in space utilisation, therefore being an indispensable tool in modern material handling. Applications also include the loading/unloading of trucks and containers, multi-level storage on racking systems with high lifting capacity, and operations on narrow aisles of compact warehouses owing to the stackers’ tight turning radius.

- Warehouses: Handling and stacking pallets to maximise storage space, organise inventories, load and unload merchandise, and shift materials across storage zones.

- Manufacturing Units: Transportation of raw materials, components, and finished goods within workstations and along production lines.

- Retail Distribution Centres: This involves the facilitation of efficient movement and storage of goods to and from large and small-scale retail operations. This enhances speed in order processing.

- Cold Storage Facilities: Temperature-sensitive products can be moved safely because of zero emissions and quiet, efficient operations.

- Pharmaceutical Industry: Bulk handling of medicines or chemical ingredients packed in containers/pallets is done with precision and care.

- E-commerce Fulfillment Centers: Sorting, moving, and organising packages quickly to ensure timely order dispatch and delivery.

- Textile Industry: Stacking, storing, and transporting rolls of fabric and related materials, including handling special pallet sizes.

- Food Processing Units: Managing ingredient and product pallets with hygiene-compliant models.

- FMCG Sector: Moving and stacking a high volume of fast-moving consumer goods for efficient distribution.

- Government and Public Warehouses: Supporting logistics operations in postal, supply, and centralised storage centers.

Why is choosing the right Battery Operated Stacker important?

To ensure safety, efficiency and longevity of operation in any warehouse or industrial setup, choosing the right battery operated stacker is important. Each specification of load capacity, maneuverability, among others, has a direct influence on productivity and operating costs. The essential factors to consider in the selection process of a battery-operated stacker for either a warehouse or storage facility are discussed below:

Load Capacity

The load capacity defines the maximum weight that can be raised and moved by your stacker safely, preventing overload-related incidents that compromise safety and longevity. With a versatile load capacity of 1,000 kg to 2,000 kg Avcon’s battery operated stackers serve various warehouse needs across industries like logistics, e-commerce, textiles, and pharmaceuticals.

Lift Height and Mast Specifications

Lift height determines how high your stacker can elevate loads for racking and storage, directly impacting vertical space utilisation. Incorrect lift heights lead to inefficient workflows, operator strain, and limited storage capacity. Avcon’s battery operated stackers feature maximum lift heights up to 6,300 mm, perfectly designed for multi-tier racking systems. This capability enables stacking to ceiling heights while maintaining stability, reducing bending during loading and improving overall warehouse throughput.

Fork Dimensions and Specifications

Fork dimensions impact compatibility with your pallet types and aisle requirements, as well as the stability of your loads. Incompatible forks create inefficiencies in operations, safety concerns, and compromised handling. Standard 1,150 mm Avcon forks are designed for Euro and industrial pallets. Forks are available custom from 1,150 mm to 1,300 mm for non-standard customer loads. Correct sizing means balanced reach, minimum aisle waste, and improved maneuverability in tight areas.

Battery Type, Run Time and Charging

Battery performance affects operational continuity and downtime. Inadequate runtime disrupts workflows, while low quality increases maintenance costs. The Avcon battery operated stackers feature robust 24V lithium-ion or lead-acid systems that provide 6-8 hours per charge. The battery discharge indicators feature hour meters for proactive scheduling; quick 2-hour charging allows multi-shift operations without mid-shift interruptions.

Manoeuvrability and Turning Radius

Tight aisles require high agility to prevent collisions and ensure maximum utilization of space. Poor turning radius results in poor navigation and throughput. Avcon’s stackers boast compact footprints with turning radiuses as low as 1,700-2,000 mm and intuitive stepless MOSFET speed control up to 5.5 km/h. The tandem wheel designs and PU wheels assure perfect command on slopes and uneven floors, ideal for Indian warehouse conditions.

Operating Environment

The equipment should be able to bear the following conditions: temperature, moisture, and floor type, among others, that may arise in corrosion or failure. Avcon stackers excel with robust mild steel construction, epoxy corrosion-resistant painting, and adaptable wheels for indoor/outdoor use. They perform reliably in textiles, pharmaceuticals, cold storage, e-commerce, and FMCG sectors across varying Indian warehouse environments.

Safety Features

Avcon’s battery operated stackers are designed to protect the operators, loads, and infrastructure while ensuring compliance. Inadequate systems expose businesses to liability and downtimes. With dead-man handles for instant braking, overload protection, emergency stops, tilt jacks for mast stability, and anti-slip traction Avcon’s battery operated stackers meet BIS, DGFASLI, OSHA, and ANSI standards to avoid tip-overs and uncontrolled movement in high-traffic areas.

Ergonomics and Operator Comfort

During long shifts, comfort reduces fatigue, errors, and turnover. Unergonomic designs lower productivity and raise injury risks. Avcon stackers are built for ergonomics with features such as ergonomic tiller heads, adjustable 45-degree handles, spring-loaded platforms, and smooth acceleration. The lower center-of-gravity balances reduce steering effort, enabling consistent performance during multi-shift operations.

Durability, Maintenance and Warranty

Durability minimises replacements for strong ROI, while easy maintenance cuts downtime and costs. Avcon’s reinforced frames, high-grade hydraulics, built-in diagnostics, and accessible parts simplify servicing to require only battery checks and inspections. A 12-month warranty covers defects, supported by national service networks and genuine spares for over 1,000 units on maintenance contracts.

Why Choose Avcon’s Battery Operated Stackers?

Avcon is India’s leading manufacturer of battery operated stackers, integrating decades of engineering heritage with modern innovation specifically for Indian industries. Here is why Avcon should be your preferred partner:

Decades of Engineering Expertise

With a legacy dating back to 1984, Avcon Systems brings over 40 years of expertise in material handling. Such depth in experience ensures that every stacker in the present lineup is not just an assembly of parts but a precisely engineered machine for stability, load safety, and longevity.

Solutions designed for Indian Warehouses

Avcon understands the unique challenges of Indian facilities—uneven floors, tight spaces, and intense duty cycles. Their battery operated stackers feature high-clearance chassis options and heavy-duty drive wheels that perform reliably where imported “light-duty” stackers often fail. Tandem load wheels provide smoother travel over floor joints and imperfections common in industrial setups.

Customisation for Specialised Applications

At Avcon Systems, we go beyond the catalogue and customise each of out battery operated stackers according to each unique operational needs. Flameproof stackers are specially engineered for hazardous zones like chemical or paint warehouses. Special Purpose Battery Operated Stackers for special purposes as well as stainless steel stackers for GMP compliant pharmaceutical and food processing industries.

Advanced Control Technology

Avcon battery operated stackers feature MOSFET electronic controllers to provide “stepless” control. That means no jerky movements-just smooth, fluid acceleration and precise lifting. Such control is vital when trying to align a heavy pallet with a high rack beam, preventing product damage and rack collisions.

Commitment to Service and Support

Buying a battery operated stacker is just the beginning of a long lasting relationship. Avcon’s strong national service network ensures spare parts and skilled technicians are never far away. With more than 1,000 units under annual maintenance contracts, they have a proven history of keeping their customers’ fleets running with an absolute minimum of downtime.

Proven Safety and Stability

Avcon prioritizes operator safety above everything. Their battery operated stackers feature Tilt Jack System and Anti-slip Traction that provides superior stability compared to other standard options available in the market. Complying with BIS and DGFASLI safety guidelines makes your operation not only productive but fully compliant with safety laws.

Conclusion

In conclusion, choosing the appropriate battery operated stacker will unlock the full use of your warehouse’s vertical space. Carefully assessing lift heights, load capacities, and manoeuvring needs, a business can achieve a solution that provides storage efficiency without expansion in floor space.

Avcon’s battery operated stackers offer a perfect blend of heavy-duty performance, precision engineering, and local adaptability. Investing in an Avcon stacker is investing in a machine that is engineered to last, designed to keep your people safe, and keep your business moving upwards.