Semi-Electric Stackers vs Fully Electric Stackers

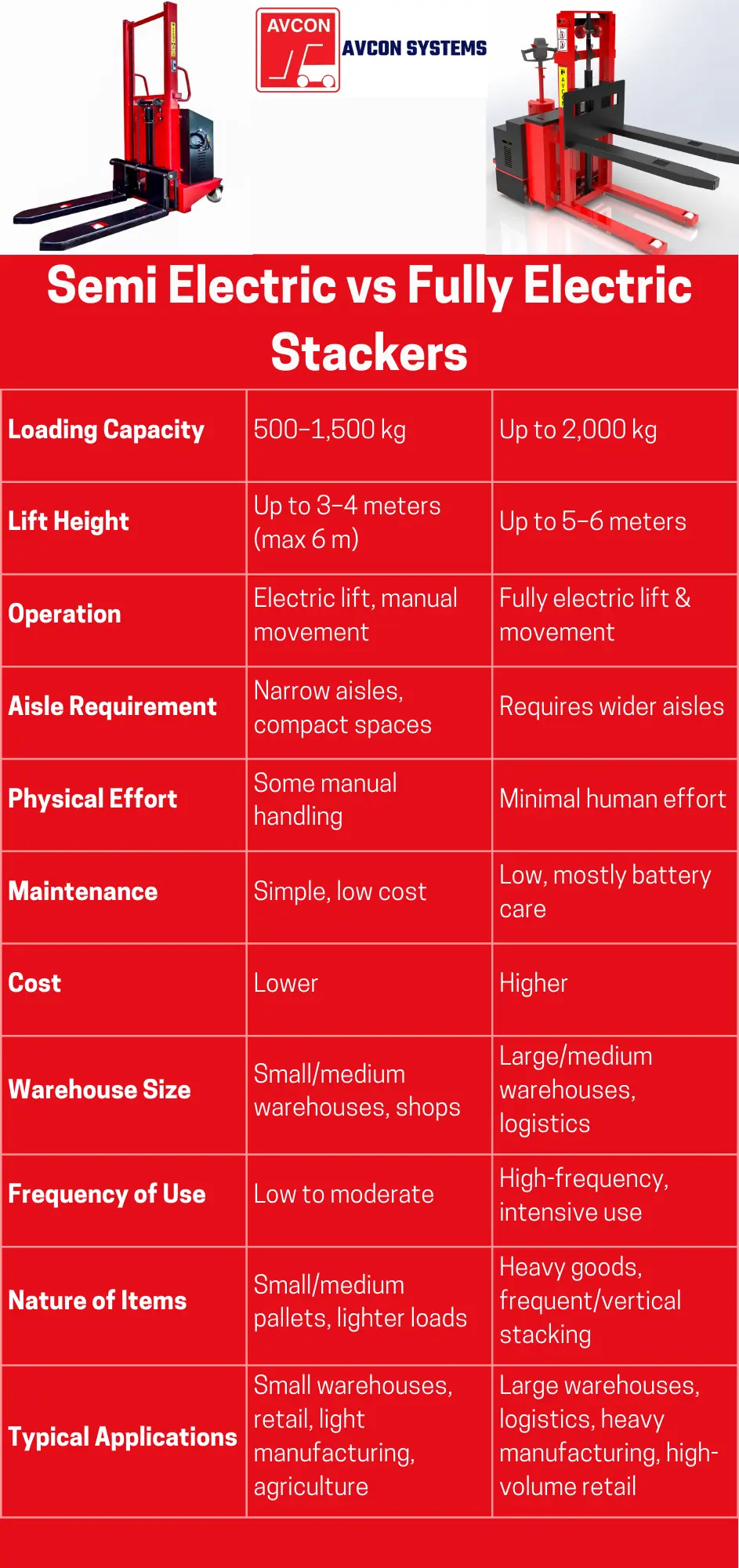

When it comes to deciding between semi-electric stackers vs fully electric stackers, it is one of the most important comparisons for facilities that want to upgrade their material handling equipment. Both types are made specifically for lifting and stacking pallets. However, semi-electric stackers and fully electric stackers have some major differences: automation, efficiency, cost, and suitability for different types of operations.

In this comprehensive guide on semi-electric vs fully electric stackers, we are going to detail all the features, benefits, and applications of both options to help you determine which stacker is best suited to your warehouse.

What Are Semi-Electric Stackers And Fully Electric Stackers?

Semi-electric stackers are pallet lifting and stacking equipment that combine electric power to lift and stack loads and manual effort to move the stacker through a hydraulic pump. Unlike a manual stacker, this reduces the manual effort in lifting and stacking items in the warehouse. However, the forward and backward movement is done manually, unlike a fully electric stacker, which operates completely on electric power through a battery charged by electricity.

A fully electric stacker eliminates manual efforts and ensures ease of lifting pallets easily, just with the click of a button. The movement of the stacker and the lifting of items are both done through electric power. This makes this stacker more preferable in large warehouses where there is too much area for the stacker to move through.

What Are The Features of Our Semi-Electric Stackers?

Semi-electric stackers provide the perfect blend of manual operation and electric assistance, making lifting easier, faster, and more efficient.

At Avcon, our designs focus on comfort, reliability, and flexibility to handle varied warehouse needs.

Motorised lifting and lowering

The stacker uses an electric motor to raise and lower loads instead of manual effort. This makes it more comfortable for the operator, reduces physical strain, and allows for quicker stacking.

AC power pack for lifting

The lifting function is powered by an AC motor and hydraulic pack. This ensures smooth, powerful, and consistent lifting performance for handling heavy loads.

No charging needed

Unlike battery-operated machines, this stacker connects directly to AC power. You don’t have to worry about charging downtime, making it ready to use whenever needed.

Adjustable fork width

The forks can be widened or narrowed to fit any pallet. This allows the operator to handle different types of pallets with one machine.

Multiple types to suit varied applications

Our semi-electric stackers are available in multiple types to suit varied applications—such as counterbalanced stackers for handling closed pallets without support legs, straddle stackers with adjustable legs for wider or non-standard pallets, platform stackers with a standing platform for operator comfort during long-distance travel, and flameproof semi-electric stackers designed for hazardous environments.

With features like AC-powered lifting, adjustable forks, and multiple configurations, Avcon’s semi-electric stackers are a practical choice for smooth and efficient pallet handling.

What Advanced Features Do Fully Electric Stackers Offer Compared to Semi-Electric Stackers?

Fully electric stackers go a step beyond semi-electric ones by automating both lifting and movement. Designed for speed, safety, and operator comfort, Avcon’s advanced models bring efficiency to demanding warehouse and industrial environments.

Wide Range of Options

AVCON makes standard and custom fully electric stackers for various applications. The AVCON range includes stackers that range from small to large warehouses; light to heavy-duty applications (including standard racking stores), as well as battery-operated stackers for special purposes. AVCON gives every industry, from retail to manufacturing, the right stacker for its handling application.

Fully Electric Operation

As the stacker is entirely electric, operators can lift, lower, and move pallets without physical effort. This increases speed and efficiency in pallet handling operations.

Smooth Speed Control

The MOSFET controller provides step-less acceleration and deceleration, so the stack doesn’t jerk upwards or stop suddenly but moves quickly off the floor, pushes & moves around a curve, then stops smoothly, protecting the operator and load.

Comfortable Handle Design

The 45° handle design provides the operator with forward and reverse movement only when the handle is at a safe angle; coupled with simple steering, this allows the operator to work comfortably without causing operator fatigue, even on longer shifts.

Battery Status Display

The stacker has a key-based battery discharge indicator on the base, giving full confidence to operators with a battery level on when it is nearly out of charge. When operators can charge it on time, the likelihood of unexpected downtime is reduced.

Easy To Maintain

The stacker has a design that provides quick access to all the major components of the stacker. Generally, this aids in reducing service time and regular maintenance, which is cost-effective.

Stand-on Platform

To facilitate longer-distance travel for the operator, a spring-loaded stand-on platform is available, so the operator rides on the stacker instead of walking behind it, increasing speed and reducing the risk of potential injury.

With smooth controls, ergonomic design, and versatile options, Avcon’s fully electric stackers deliver faster, safer, and more reliable pallet handling. They are built to reduce effort, minimize downtime, and adapt to every application with ease.

What Are The Advantages Of Semi-Electric Stackers?

Avcon’s semi-electric stackers are designed to bridge the gap between manual and fully electric solutions—offering affordability, ease of use, and reliable performance. They bring a wide range of benefits that make them ideal for growing businesses and busy warehouses.

1. Cost-Effective Operation

The most significant advantage of Avcon’s semi-electric stackers is that they are competitively priced compared to fully electric stackers. Avcon’s semi-electric stackers are much lower in price than fully electric stackers, but still provide electric lifting capability. Because the power source is alternating current, there is no battery monitoring, and there is no continued cost of maintaining or replacing batteries. This is very favorable for businesses looking for improvements regarding operational efficiencies without a large commitment of capital.

2. Instant Usage with Plug-and-Play Design

The semi-electric stackers from Avcon have a plug-in to operate capability. This means you can use them right away. There is no waiting for the batteries to charge. This benefit of AC power supply means no downtime, even if your day includes continuous or breakneck speed handling of product with no place for recharging. These are ideal for serious warehouse and busy workplaces that require reliable products that are in use all day.

3. Reduced Physical Strain and Improved Safety

The electric raising setup reduces the physical effort needed from operators significantly. Workers do not have to pump hydraulic handles by themselves to lift the heavy loads of pallets, therefore lowering the chances of workplace injuries and fatigue. This will certainly improve worker safety and help increase productivity.

4. Enhanced Operational Efficiency

Avcon’s semi-electric stackers are a great improvement that will speed up the stacking process because the stackers have motorized lifting and lowering devices. The inching type lifting and lowering function allows for more precise control, making it easier for operators to position the load exactly where required. The automation of the lifting and lowering process avoids human error and enhances efficiency in the overall process.

5. Versatility for Different Applications

The semi-electric stackers manufactured by Avcon offer adjustable fork width in order to accommodate different pallet sizes. They are a medium-duty stacker with a load capacity of up to 1,500 kg with a maximum lifting height of 3,500 mm, offering many potential applications for material handling in warehouses, logistics, pharmaceuticals, textiles, and food processing.

6. Better Space Utilisation

These stackers help to maximise warehouse space by allowing pallets to be stacked vertically. Being able to stack goods higher means there are fewer products on the floor and better organisation of the inventory. Higher stacking capabilities give businesses the potential to store even more products in the same floor space.

7. Easy Operation and Maintenance

Avcon’s semi-electric stackers are designed with simple, user-friendly controls that require minimal training for employees. The maintenance-free models help reduce downtime and service costs compared to other equipment. The simple operation allows employees to easily adapt and start using the equipment productively in no time.

8. Improved Productivity and Throughout

Case studies indicate increased productivity for companies using Avcon semi-electric stackers through improved loading, unloading, and stacking activities. Reduced idle time and more efficient procedures improve throughput and also shorten delivery time, which improves the bottom line.

9. Scalability for Growing Businesses

Semi-electric stackers offer a versatile solution that will grow with your business. They help resolve operational bottlenecks while controlling costs, allowing for future growth modelling. When business grows, semi-electric stackers can increase material handling and storage without large equipment investments.

From cost savings and instant usability to improved safety, efficiency, and scalability, Avcon’s semi-electric stackers provide a smart material handling solution. They help businesses boost productivity while keeping operations simple, reliable, and future-ready.

Semi-Electric Stackers vs Fully Electric Stackers: Why are warehouses shifting from semi-electric stackers to fully electric stackers?

Many warehouses are moving from semi-electric to fully electric stackers as operations demand greater speed, safety, and efficiency. Avcon’s fully electric models deliver complete automation and advanced features that make them the smarter choice for modern material handling:

1. Complete Automation for Maximum Efficiency

Unlike semi-electric stackers, where the operator must physically push and pull, Avcon’s electric stackers provide motorised controls for both lifting and travel. With full electric, there is no manual push/pull of loads, making the operation three times faster than semi-electric models. Operators can quickly transport odd-shaped and heavy loads across long distances with little effort and no restriction on travel speed.

2. Superior Performance Capabilities

Compared to the 1.5 tons and 3.5 meters of a semi-electric stacker, Avcon’s electric stackers handle loads of up to 2 tons and can lift heights of 6 meters or more. Avcon’s stacker uses a MOSFET-based controller, which allows for smooth, stepless acceleration and deceleration control, providing operators with precise handling when navigating amongst many obstacles in a busy warehouse.

3. Enhanced Safety Features

Avcon electric stackers are also designed with many safety features, such as a battery discharge indicator to prevent the vehicle from shutting down unexpectedly, and with ergonomically designed handles set at a 45-degree angle so the operator can work comfortably. The tilt jack system provides load stability when travelling, so that the risk of possible accidents is reduced significantly compared to moving loads manually with a semi-electric stacker.

4. Long-Term Cost Benefits

While an electric stacker has a higher upfront cost, the overall value is greater in the long run, due to lower labour costs and higher productivity. This is in part due to a more rugged battery life and longevity, but also due to having a very low maintenance cost. On top of all of that, companies can do much more with less labour.

5. Ideal for High-Volume Operations

A fully electric stacker is a great option for larger warehouses or frequent movement of pallets. They are designed for high-frequency lifting applications where speed and efficiency are important. The spring-loaded stand-on platform accessory increases the travel speed, allowing perfect functionality of these trucks in high traffic areas, as you normally would when operating table lifters in a large area or going to different levels.

6. Better Maneuverability

While more powerful, Avcon’s fully electric stackers manoeuvre very well and allow for easy access for maintenance. Their compact designs are also made to take up less space, and yet still operate in narrow aisles. The advanced control systems allow for much better steering and spatial awareness than semi-electric stackers that rely on human force to move.

7. Future-Ready Technology

Fully electric stackers embody the newest advances in material handling, boasting features such as quiet operation and energy-efficient motors. These new models can fully replace conventional forklifts and manual handling tasks, making them a forward-thinking investment for any growing business.

With greater capacity, greater maneuverability, and more future-proof technology, fully electric stackers will allow for superior productivity in high-volume operations. For warehouses looking to maximise productivity and remain competitive, Avcon’s fully electric stackers are the natural next step.

Semi-Electric Stackers vs Fully Electric Stackers: Key Application Differences

1. Applications of Semi-Electric Stackers

Semi-electric stackers are widely used in environments where moderate lifting power is needed, combined with manual mobility. Their applications include:

- Small to Medium Warehouses:

Ideal for warehouses with limited space where compact and maneuverable equipment is needed. Their small size and lack of counterweight make them suitable for narrow aisles and confined spaces. - Retail and Supermarkets:

Perfect for use in building supermarkets or retail outlets for shelving, stocking, and moving goods without heavy lifting machinery. - Agriculture and Manufacturing:

Used for material handling in manufacturing units and agricultural warehouses where loads need to be stacked or moved, but the space or budget does not allow for fully electric stackers. - Light Industrial and Commercial Operations:

Suitable for light to medium duty lifting tasks where loads typically range up to 1,000-1,500 kg and lifting heights to around 3.5 meters. - Warehousing and Distribution Centres:

Efficient for low-to-medium frequency pallet stacking, order picking, and loading/offloading pallets. - Cost-Conscious Operations:

Often chosen due to affordable price, low maintenance needs, and moderate operator effort (requires manual pushing/pulling). - Environmentally Sensitive or Indoor Use:

Because they do not emit exhaust gases, they are usable in closed indoor spaces without ventilation concerns. - Noise-Sensitive Areas:

Their low noise levels make them suitable for use in shops or customer areas.

Semi-electric stackers have electric lifting motors but rely on manual movement, making them efficient for applications where lifting automation is needed but continuous electric travel is not required.

2. Applications of Fully Electric Stackers

Fully electric stackers provide electric-powered lifting and movement, making them suitable for more intense and frequent operations:

- Large Warehouses and Distribution Centres:

Well-suited for large warehousing spaces where high-frequency stacking, unstacking, and loading tasks are required. - E-commerce and High Volume Fulfillment Centers:

Perfect for environments where speed, efficiency, and operator safety in handling heavy loads are critical. - Multi-level Storage Facilities:

Can handle high lifting heights (up to 6 meters or more), making them ideal for vertical storage systems and multi-tier racking. - Heavy-Duty Industrial Operations:

Suitable for moving heavy loads of 1,500-3,000 kg or more with minimal operator effort. - Tight Aisle and Dense Storage Layouts:

Due to their electric travel and powered lifting, they efficiently maneuver in narrow aisles while maximising space utilisation. - Continuous or Multi-Shift Use:

Can operate longer hours with battery life supporting extended work periods; ideal for multi-shift operations. - Improved Safety and Ergonomics:

Reduce operator fatigue and risk of injury by automating movement and lift controls. - Specialised Warehousing Needs:

Including cold storage, pharmaceuticals, and food processing, where clean, electric-powered equipment is preferable. - Operations Requiring Higher Precision and Speed:

Electric drive offers consistent travel speed and smooth control, supporting faster loading/unloading cycles.

Fully electric stackers are best for businesses that require mechanised high efficiency, higher-lifting-capacity, and automation in material handling workflows.

Semi-Electric Stackers vs Fully Electric Stackers: Which stacker should you choose for your warehouse?

Semi-electric stackers offer a great alternative to manual pallet jacks, particularly in small to medium warehouse environments that handle light or medium work volume at delivery placements or stock rotation areas. They are low-cost, easy to operate, and have a smaller footprint for tight spaces and shorter travel distances. The worker will still need to do the pushing and steering, and lifting (although lifting is powered and reduces manual lifting strain). If your warehouse is small with narrow aisles and stock is moved infrequently or with moderate volumes, a semi-electric stacker is a good option for you, as well as if you want to keep costs and maintenance to a minimum.

Our fully electric stackers offer greater efficiency and improved safety levels for larger warehouse applications with higher volumes of pulling/freight locations. These automatic stackers enable workers to travel using less effort, even when requiring higher levels of product movement with frequent and potentially longer distances. Fully electric stackers are more expensive but enable efficient movement between multiple spaces. In large setups and areas that move high volumes daily or handle product returns, this is a significant benefit, particularly if your workers are completing shifts carrying heavier items. Fully electric stackers will improve productivity and decrease workers’ fatigue.

Semi-electric stackers provide the ideal balance of efficiency, reliability, and cost-effectiveness for the vast majority of warehouses. For heavy-duty, high-volume environments, fully electric stackers offer the necessary speed and safety to meet growing demands.

Discover the perfect stacker solution tailored to your warehouse—explore our innovative range of semi-electric stackers and fully electric stackers designed to boost efficiency, save space, and match your unique operational needs with ease and reliability.