Choosing the right battery operated pallet trucks is a crucial decision that directly impacts the efficiency, safety, and productivity of your warehouse operations. With multiple models, specifications, and applications available, understanding what these machines do and how to select the right one becomes essential for any modern facility.

This comprehensive buying guide explains everything you need to know before making a purchase. Whether you’re upgrading your current fleet or investing for the first time, this guide will help you make an informed, confident decision.

What are battery operated pallet trucks?

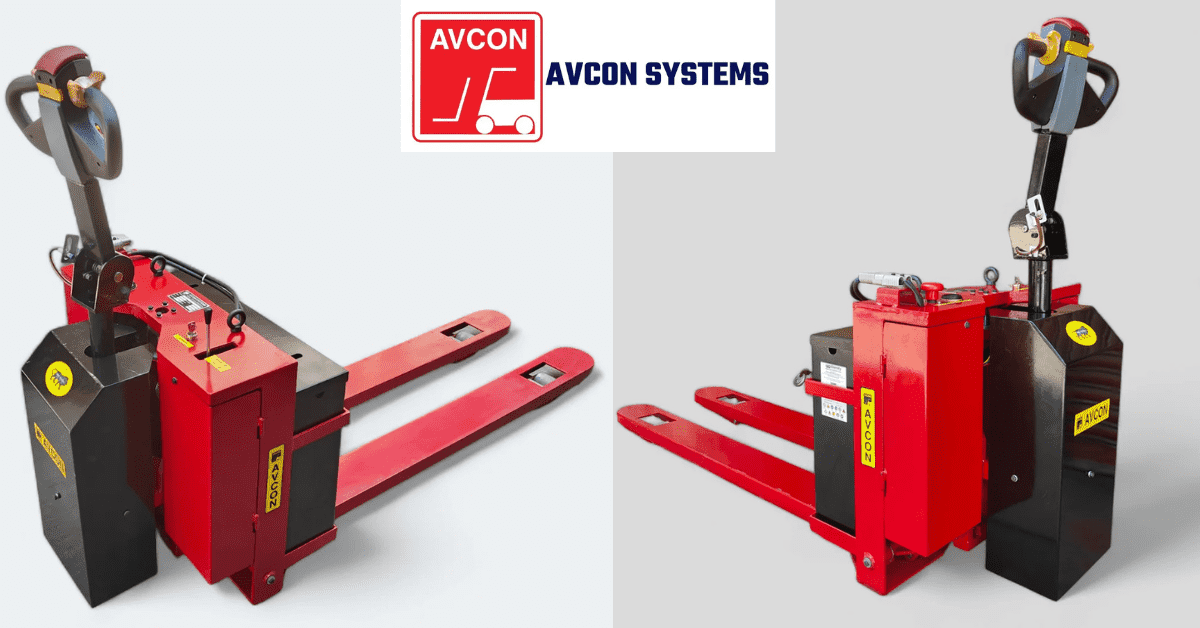

Battery operated pallet trucks are a material handling equipment powered by rechargeable batteries that transports pallets horizontally across warehouse floors. The electric powered pallet truck uses an electric motor to raise the forks and propel the truck, making it more efficient and less physically demanding than manual versions. It is ideal for moving loads up to several tons in industrial settings like distribution centers.

The battery operated pallet trucks manufactured by Avcon Systems excels in long-distance pallet transfers with simple user-friendly controls and built-in safety features. It also offers a robust construction for durability in harsh environments along with low maintenance due to easily accessible design and in-built diagnostics.

What are the various applications of Battery Operated Pallet Trucks?

Battery Operated Pallet Trucks can be utilised for many different operations, across many industries and warehouse functions. They are used to improve material handling efficiency and reduce labour in the following situations:

- Loading and unloading products in warehouses and distribution centers

- Transporting pallets long distances within storage facilities

- Order picking and fulfilment in e-commerce and retail warehouses.

- Inventory re-organisation and shelving stocking projects.

- Moving material in manufacturing plants and assembly operations

- Used in the pharmaceutical and food processing industry for hygienic handling of pallets.

These battery operated trucks are mostly used indoors, where they provide smooth, fast, and safe movement of products, improving overall workflow and throughput while minimising operator fatigue.

Why choosing the right Battery Operated Pallet Trucks is important?

Choosing the right battery operated pallet trucks for your warehouse is a strategic decision that directly impacts your operations. An unsuitable pallet truck can lead to inefficiencies, safety hazards, increased costs and bottlenecks while the optimal choice optimises workflow, protects workers, and supports long-term business goals. Here are some of the reasons why choosing the right battery operated pallet trucks is important:

Operational Efficiency and Productivity

Warehouses thrive on speed and reliability, and the wrong pallet truck can create bottlenecks by slowing down pallet movement or requiring frequent interventions. A well-chosen electric pallet jack, such as the battery-operated pallet truck offered by Avcon Systems, with motorised lifting and propulsion, enables faster transportation of goods. Features like step-less speed control and ergonomic handles further streamline tasks, allowing operators to handle more pallets per shift.

Enhances Workplace Safety

The right battery operated pallet trucks incorporate advanced safety features tailored to your operations, such as emergency stop buttons, automatic braking systems, anti-slip platforms, overload protection, and anti-rollaway mechanisms, which prevent uncontrolled movement on inclines. Selecting a model with a turning radius suited to narrow aisles reduces collision risks while proper weight capacity matching avoids overloading that could cause tip-overs or structural failures. Avcon’s battery operated pallet truck offers safety features ensuring operator safety, avoiding accidents and leading to smooth operations.

Improves Operator Comfort

Warehouse workers often spend hours operating pallet trucks, so ergonomics directly affect morale, productivity and error rates. The ideal model minimises fatigue and repetitive strain injuries.

Ensures Adaptability to your Warehouse Environment

Warehouses differ in terms of floor type, aisle width, temperature and load profiles that demand customised floor cranes. Battery Operated Pallet Truck provides various customisation options like customisable fork lengths,

Promotes Durability, Maintenance and Sustainability

A well engineered battery operated pallet truck model should withstand daily rigour,s and selection determines longevity. The right model should have a robust design, built in diagnostics, high-grade hydraulics, and easily accessible parts to simplify maintenance.

Our electric models reduce emissions over gas-powered alternatives, aligning with sustainability goals. Lithium iron batteries eliminate the need for watering. The right model leads to energy efficiency, minimum waste and lowers operational costs.

What are the factors to consider while choosing battery operated pallet trucks?

Choosing the right battery-operated pallet truck is essential for ensuring safety, efficiency, and long-term performance in any warehouse or industrial setup. Each specification, from load capacity to manoeuvrability, directly affects productivity and operating costs. Below are the key factors to consider while choosing a battery operated pallet truck for your warehouse or storage facility.

Load Capacity

Load Capacity determines the maximum weight your pallet truck can safely transport, preventing overload incidents that compromise safety and longetivity. Avcon battery operated pallet trucks offer versatile load capacities ranging from 1,500 kg to 2,500 kg, accommodating diverse warehouse requirements. The standard 2,000 kg capacity model is engineered to handle typical palletised loads across industries like logistics, e-commerce, textiles, and pharmaceuticals.

Lift Height and Fork Dimensions

Lift height determines how easily your truck can slide beneath pallets and position them at optimal unloading heights. Incorrect lift heights lead to operator strain, inefficient workflows, and potential damage to goods.

Avcon’s battery operated pallet trucks feature a maximum lift height of approximately 200 mm, perfectly designed for standard warehouse operations. This height is engineered to slide smoothly under industrial pallets while elevating loads to comfortable unloading heights at truck beds and conveyor systems. The optimal lift height reduces bending and awkward positioning, enabling operators to work more efficiently.

Fork Dimensions and Specifications

Fork dimensions directly influence compatibility with your pallet types, aisle requirements, and overall warehouse space utilisation. Mismatched fork dimensions result in operational inefficiencies, safety hazards, and compromised load stability. Proper fork sizing ensures maximum throughput while maintaining ergonomic efficiency and safety compliance across diverse warehouse operations.

Fork length determines how far your truck extends into the warehouse space and how comfortably it handles different pallet types. Avcon’s standard fork length of 1,150 mm is engineered for Euro pallets (1,200 mm × 800 mm) and standard industrial pallets. This length provides optimal balance between reach capability and manoeuvrability. For specialised applications requiring extended capacity, Avcon offers customizable fork lengths ranging from 1,150 mm to 1,300 mm, accommodating non-standard pallets, roll containers, and custom-sized loads. Longer forks excel in deep-loading scenarios where pallets stack behind warehouse racks, while shorter forks enhance agility in tight-aisle environments.

Selecting the correct fork length minimises wasted aisle space and maximises load handling efficiency without sacrificing turning radius or warehouse throughput.

Battery Type, Run Time and Charging

Battery performance directly impacts operational continuity. Insufficient runtime leads to frequent charging stops that disrupt workflows, while poor battery quality causes unexpected downtime and inflated maintenance costs.

Avcon battery operated pallet trucks are equipped with robust 24V battery systems engineered for full-shift performance. With an impressive runtime of 6 to 8 hours per charge, Avcon trucks operate continuously throughout standard warehouse shifts without requiring mid-shift recharging. The battery discharge indicator with integrated hour meter displays real-time battery status, enabling proactive maintenance scheduling and preventing unexpected power loss. Avcon’s recommended charging protocol—charging when the battery drops to 20%, completing full charge cycles, and avoiding overcharging—maximises battery lifespan and reliability.

Manoeuvrability and Turning Radius

Tight warehouse aisles and complex layouts demand exceptional maneuverability. Poor turning radius compromises efficiency and increases collision risks, while superior agility enables faster navigation and higher throughput.

Avcon’s battery operated pallet trucks are specifically designed for Indian warehouse environments with their compact footprint and responsive steering. The intuitive stepless MOSFET speed control allows operators to adjust acceleration smoothly, providing precise command in narrow aisles and crowded areas. The tandem tail wheel fork design enhances directional control while stabilising the truck on slopes and uneven surfaces, a critical advantage in diverse Indian warehouse conditions. This advanced configuration reduces turning radius, enabling operators to navigate tight corners efficiently. Combined with PU (polyurethane) wheels that minimise friction and improve handling on various floor surfaces, Avcon trucks deliver superior agility without sacrificing load stability, accelerating material flow and maximising warehouse space utilisation.

Operating Environment

Material Handling Equipment must perform reliably in the specific conditions it encounters. Environmental mismatches due to temperature extremes, moisture and rough terrain lead to corrosion, mechanical failure and shortened equipment life.

Avcon battery operated pallet trucks excel across diverse operating environments, making them ideal for multi-industry deployments. Whether navigating smooth warehouse floors or handling rough outdoor terrain, these trucks are engineered with robust mild steel construction, epoxy painting for corrosion resistance, and adaptable wheel options that accommodate both indoor and outdoor surfaces.

Avcon’s battery operated pallet trucks operate reliably in textiles, pharmaceuticals, rubber processing, e-commerce, FMCG, food processing, and government sectors-industries with varying environmental demands. The sturdy construction and versatile wheel materials ensure consistent performance across temperature ranges and floor conditions typical in Indian warehouses, while the proven design withstands the rigors of high-volume, multi-shift operations.

Safety Features

Operator safety directly impacts workplace culture, reduces injury related downtime and ensures regulatory compliance. Inadequate safety features expose businesses to liability and worker compensation claims.

Avcon prioritizes comprehensive safety with multiple integrated features engineered into every battery-operated pallet truck. The dead man handle requires operators to maintain a 45-degree position for continuous operation; releasing the handle instantly engages automatic braking, preventing uncontrolled movement. This intelligent design is especially critical in high-traffic warehouse environments. Advanced stability controls and the tandem tail wheel fork design prevent tipping on slopes and uneven terrain, protecting both operator and load. Overload protection systems prevent the truck from lifting loads beyond its rated capacity, while safety interlocks prevent dangerous operating conditions.

Avcon’s battery operated pallet trucks meet stringent Indian safety standards including BIS and DGFASLI guidelines, with select models complying with international standards like OSHA and ANSI.

Ergonomics and Operator Comfort

Operator comfort directly correlates with productivity, safety, and long-term employee retention. Uncomfortable equipment leads to fatigue, reduced throughput, errors, and higher injury rates over extended shifts.

Avcon’s battery operated pallet trucks are engineered with operator comfort at the core of their design philosophy. The ergonomically designed tiller head and intuitive controls minimise fatigue, even during extended shifts, enabling operators to work with efficiency throughout the day. The stepless MOSFET speed control delivers smooth, responsive acceleration that reduces operator strain and provides predictable handling characteristics. Adjustable speed settings allow customisation to individual operator preferences and specific task requirements, enhancing comfort and control. The truck’s well-balanced design with a lower centre of gravity reduces the physical effort required for steering and maneuvering, particularly important during high-volume, multi-shift operations.

By reducing fatigue compared to manual pallet trucks, Avcon’s battery-operated models enable operators to maintain consistent performance and focus on safety throughout their shifts.

Durability, Maintenance, and Warranty

The durability of material handling equipment reduces replacement frequency and gives a good return on investment. Straightforward maintenance minimises labour cost and downtime. Comprehensive warranty protections provide financial security and demonstrate manufacturer confidence in product quality.

Avcon’s Battery Operated Pallet Truck offers simplified maintenance requiring nothing more than regular battery checks, hydraulic inspections and built in diagnostics. Avcon backs its battery operated pallet trucks with a 12-month warranty, reflecting the manufacturer’s confidence in product quality. This warranty covers manufacturing defects and provides peace of mind during the critical initial operating period. Combined with Avcon’s commitment to after-sales service, you gain access to rapid support and genuine spare parts, ensuring your equipment remains productive long after the warranty period expires.

Why choose Avcon’s Battery Operated Pallet Trucks?

Avcon stands out as the manufacturer of choice for battery operated pallet trucks in India due to their engineering expertise, tailored solutions for the Indian market, and proven reliability across industries. Here’s why Avcon should be your preferred battery-operated pallet truck manufacturer:

Decades of Engineering Expertise

Avcon Systems has been a leader in material handling equipment manufacturing since 1984, founded by Mr. V.S. Sawarkar, who brings over 45 years of industry experience. This legacy means every Avcon truck is backed by deep engineering knowledge and a commitment to quality that spans generations.

Solutions Designed for Indian Warehouses

Unlike one-size-fits-all imports, Avcon’s battery-operated pallet trucks are engineered specifically for Indian warehouse layouts and challenges. Their compact, robust chassis, reinforced fork designs, and tandem tail wheel configuration tackle narrow aisles, sloped floors, and mixed surface conditions common in Indian facilities. This ensures reliable, safe, and efficient operations tailored to local demands.

Versatile Industry Integration

Avcon serves a wide spectrum of industries—including textiles, pharmaceuticals, food processing, rubber, e-commerce, logistics, government, and more—with battery-operated pallet trucks that match diverse application needs. Their product portfolio includes customizable fork dimensions, load capacities, wheel types, and advanced safety features to meet any warehouse or shopfloor requirement.

Customisation for Operational Excellence

Avcon offers significant flexibility in specification: you can choose fork lengths (typically 1,150–1,300 mm), fork widths, load capacities (up to 2,500 kg), and materials such as mild steel or stainless steel, ensuring complete compatibility with your existing infrastructure and operational goals. They also provide equipment for GMP-compliant pharmaceutical zones and heavy-duty engineering shops.

Commitment to Service and Support

With a robust national after-sales support network, Avcon maintains over 1,000 units under annual maintenance contracts, delivering prompt technical support and spare parts from regionally positioned service engineers. This minimises downtime and protects your investment far beyond initial purchase.

Proven Durability and Safety

Avcon trucks feature reinforced frames, advanced ergonomic handles, and multiple wheel options for different floor conditions, supported by key safety features such as tandem tail wheels for gradeability and load stabilisation. Their focus on safety and durability ensures low maintenance, minimal breakdowns, and reliable performance in demanding environments.

Leadership in Material Handling Innovation

Continuously innovating, Avcon integrates ergonomic design with cost-effective manufacturing to maximize operational efficiency and safety for every customer. Their goal is to deliver high-quality, reliable solutions and set industry standards for battery-operated pallet trucks in India.

Choosing Avcon as your battery operated pallet truck manufacturer means investing in tailored engineering, long-lasting reliability, true customisation, and responsive support founded on decades of experience and leadership in the Indian material handling industry.

Conclusion

In conclusion, selecting the right battery operated pallet truck is vital to enhancing warehouse efficiency, safety, and overall productivity. By understanding the key factors such as load capacity, battery life, maneuverability, and safety features, businesses can choose trucks tailored to their unique operational needs.

Avcon’s battery operated pallet trucks stand out for their robust design, ergonomic controls, and industry-specific customizations, making them a trusted choice in India. Investing in a high-quality battery operated pallet truck helps streamline material handling, reduce operator fatigue, and support sustainable warehouse practices—ensuring long-term operational success.