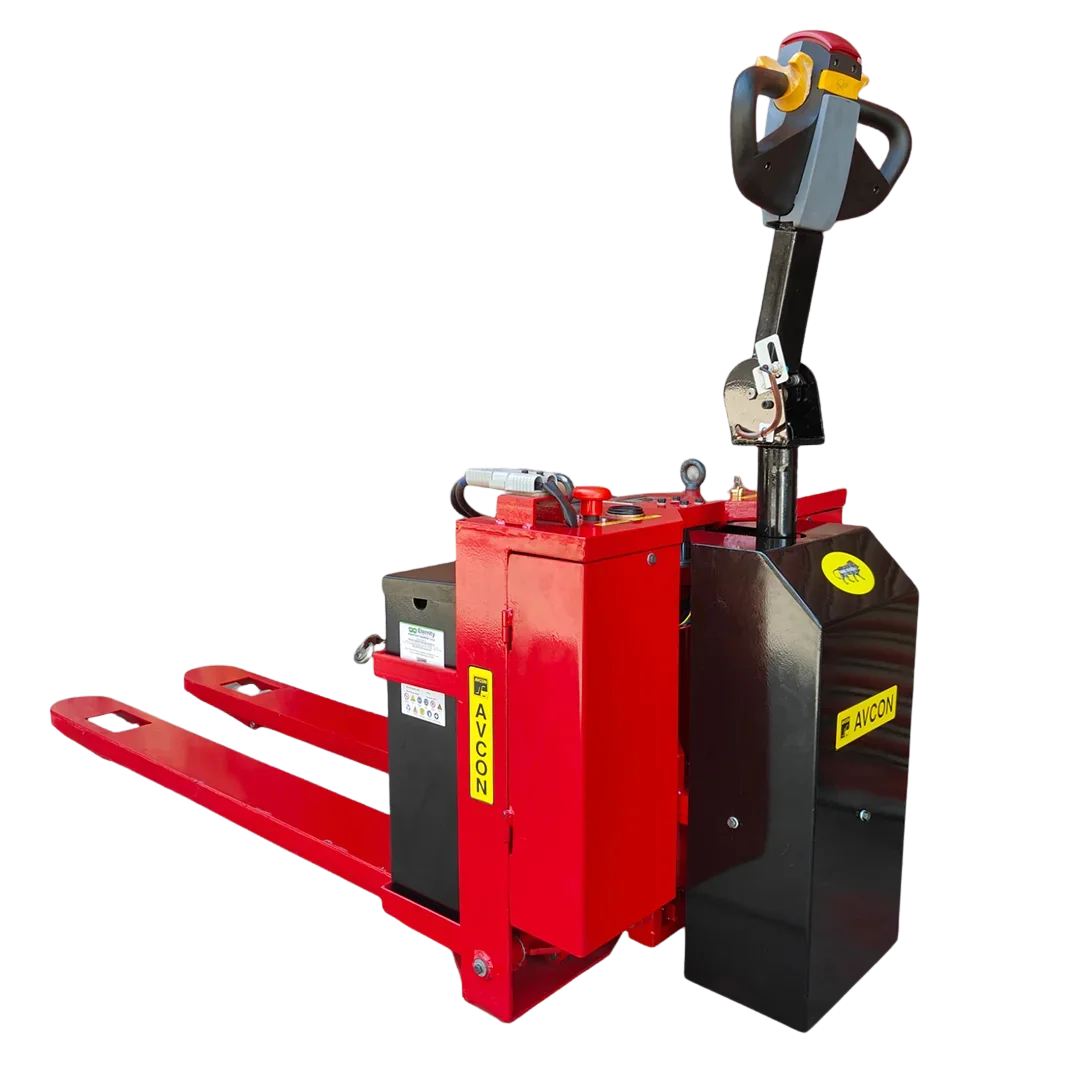

Redefining Pallet Movement with Avcon’s Battery Operated Pallet Truck

Effortlessly move pallets with electric drive, speed up loading and unloading, and reduce operator fatigue while boosting efficiency.

Challenges Warehouses Face Without

Avcon’s Battery Operated Pallet Truck in India

Modern warehouses face increasing pressure to deliver faster, safer, and more efficient operations. Yet, many facilities still rely heavily on manual handling and outdated equipment — leading to productivity bottlenecks and safety risks.

Key Challenges:

- Manual Labor Dependency: Workers spend hours pushing and pulling heavy loads, leading to fatigue and slower turnaround time.

- Low Productivity: Manual pallet movement limits throughput and affects timely dispatch and delivery.

- Safety Concerns: Repetitive strain and improper handling increase the risk of workplace injuries.

- Space Utilization Issues: Narrow aisles and unoptimized layouts restrict movement and operational flow.

- Equipment Downtime: Conventional pallet jacks require more effort and maintenance, adding to inefficiencies.

Avcon’s Battery Operated Pallet Truck: The Solution

Avcon’s battery operated pallet truck delivers a powerful alternative to manual handling combining ergonomic handling design with advanced technology to transform material handling operations. Built with over 40 years of material handling expertise since 1984, Avcon offers fully electric pallet truck, a solution specifically engineered for the demanding conditions of Indian warehouses.

Avcon’s battery operated pallet truck eliminates manual effort with smooth motorised movement and intuitive controls. Designed for long shifts, they deliver consistent performance and efficiency with minimal downtime. Safety remains a top priority, featuring intelligent braking and built-in monitoring systems that ensure reliable, secure, and effortless operation throughout the workday.

How Avcon Solves Warehouse Challenges:

- Eliminates Manual Labour Dependency

Operators can easily move pallets up to 1,500 kg without physical strain, reducing fatigue by 40% and increasing productivity during loading and unloading. - Boosts Productivity Dramatically

Electric propulsion speeds up pallet movement, enabling faster transport over longer distances and improving overall dispatch and delivery efficiency. - Enhances Workplace Safety

Advanced safety features like automatic brakes, emergency stops, and anti-roll-back systems greatly reduce workplace injury risks. - Space Optimisation

Easily navigate narrow aisles, maximising storage and improving workflow without altering warehouse layouts. - Minimises Equipment Downtime

Requires less maintenance due to robust frame with fewer moving parts translating into lower operational costs and reduced downtime.

Features of Battery Operated Pallet Truck

High Efficiency

Powered electric drive lets you move more pallets faster and farther, boosting throughput.

Operator Comfort

Ergonomically designed controls and intuitive tiller head reduce fatigue and enhance ease of use

Long Battery Life

Built to last a full shift with reliable battery performance, minimizing recharging stops.

Built-in Safety

Features like a dead‑man handle, automatic braking and anti‑roll‑back give top‑tier protection in operation.

Low Maintenance

Fewer moving parts plus built‑in diagnostics streamline upkeep and keep downtime low.

Smooth Maneuvering

Compact design and stepless speed control deliver precision handling even in narrow aisles.

Reduce Manual Effort and Boost Productivity

Advantages of Battery Operated Pallet Truck

1. Operational Simplicity

Effortless operation with customisable, stepless speed control, ensuring smooth handling, reduced training time, and adaptability to various warehouse needs.

2. Enhanced Control and Stability

Engineered for operator safety, Avcon’s battery powered pallet truck combines a dead man handle, automatic braking, and advanced stability controls to ensure secure, precise, and fatigue-free operation. A tandem tail wheel fork design that ensures stability and traction on slopes and uneven surfaces.

3. Versatility and Adaptability

Built for versatility in both indoor and outdoor settings, with their ergonomic design reducing strain, enhancing comfort and boosting long-term productivity.

4.Maintenance and Serviceability

Designed for easy maintenance, built-in diagnostics and simple inspection routines, minimising repairs and downtime, reducing operation costs.

5. Tailored to Operational Requirements

Customisable options with adjustable fork lengths, specialised attachments and optional accessories, ensuring each unit is tailored for specific operational needs and load types.

6.Performance and Monitoring

The battery discharge indicator with hour meter helps track battery status and usage, enabling proactive maintenance and preventing unexpected downtime.

7. Extended Battery Life

Impressive battery life lasting 6-8 hours of runtime per charge, ensuring uninterrupted workflow, higher efficiency, and fewer battery swaps.

8. Multiple Industry Compatibility

Serves multiple industries: textiles, pharmaceuticals, rubber, e-commerce, logistics, paint, food processing, FMCG, and government sectors, making them a versatile and reliable choice for diverse material handling needs.

Technical Specification

Load capacity

2,000 kg

Max lift height

~200 mm

Fork length (typical)

~1,300 mm

Wheel type

PU (Polyurethane)

Power source

Battery operated, 24 V system (varies by model)

Controller

MOSFET step-less speed control

Safety/Ergonomics

Dead-Man handle, battery discharge indicator with hour meter

Use case

Warehouse floor transport, warehouse transfer of pallets

Why Choose Avcon

Material Handling Manufacturers You Can Trust

At Avcon Systems, we deliver more than material handling products — we provide complete, performance-driven solutions backed by 45+ years of expertise, reliable after-sales support, and a strong customer-first approach.

In-House Manufacturing

Every Avcon product is designed, fabricated, and tested under one roof to ensure consistent quality and precision in performance.

Advanced Technology

Our systems integrate hydraulic, electric, and automation technologies for efficient and reliable handling operations.

Durability & Low Maintenance

Avcon machines are made from heavy-duty materials with corrosion-resistant coatings, ensuring long life and minimal service downtime.

Custom-Engineered Solutions

We specialize in tailor-made equipment that fits your specific industrial process, floor space, and operational needs.

Safety & Compliance

Each product is built following strict ISO and CE standards, featuring overload protection and stable lifting mechanisms.

Complete Support

From installation to maintenance and after-sales service, our team ensures smooth and worry-free operation throughout your equipment’s life cycle.

Switch to Battery Power and Simplify Your Pallet Movement.

Achievements

Our Nationwide Customer Base

We are proud to serve customers all over India, including Goa, Ahmedabad, Surat, Baroda, Bhopal, Kolkata, Madurai, Coimbatore, Diu and Daman, Haridwar, Uttarakhand, Rudrapur, Odisha, Bhubaneswar, Morbi, Udaipur, Hyderabad, Baddi, Chandigarh, Manesar, Bhiwandi, Silvassa, Vapi, Tarapur, Bewandi, Mahape, Ambernath, Sangli, Satara, Alibaug, Kolhapur, Sikkim, Darjeeling, Lucknow, Mangalore, Vijayawada, Vizag, Amritsar, Manipur, Guwahati, Indore, Noida, Gurgaon, Jammu, Thane, Chennai, Bangalore, Nashik, Nagpur, Pune, and Mumbai.

FAQS -Avcon Battery Operated Pallet Truck

Avcon battery operated pallet trucks provide a battery life that typically lasts a full shift of standard operation, ranging from 6 to 8 hours on a single charge. This ensures uninterrupted workflow throughout the workday and reduces the need for frequent recharging, enhancing operational efficiency for your warehouse.

Avcon battery operated pallet jacks can handle various pallet types and loads, and are designed for both indoor warehouse floors and outdoor terrain, making them versatile for multiple industries including logistics, manufacturing, pharmaceuticals, and e-commerce.

Avcon’s battery-operated pallet trucks meet key Indian safety standards, including BIS and DGFASLI guidelines, with features like emergency stops, safety interlocks, and overload protection. Proper operator training is emphasized, and select products also comply with international standards like OSHA and ANSI.

To ensure long battery life and reliable operation of your Avcon pallet truck: charge when it drops to 20%, complete full charge cycles, avoid overcharging, inspect terminals daily, maintain electrolyte levels for lead-acid batteries, store in a cool, ventilated area and use the proper recommended charger.

Avcon pallet jacks can handle various pallet types and loads, and are designed for both indoor warehouse floors and outdoor terrain, making them versatile for multiple industries including logistics, manufacturing, pharmaceuticals, and e-commerce.

Yes, they feature straightforward maintenance such as battery level checks, hydraulic inspections, and built-in diagnostics for troubleshooting, streamlining upkeep and minimizing downtime.

Absolutely! Avcon offers customization including different fork lengths, widths, specialised attachments, and accessories so customers can adapt the trucks to their specific material.

Avcon battery operated pallet trucks typically support load capacities up to 1,500 to 2,500 kg depending on the model. Fork lengths generally range around 1,150 mm, with fork widths between 550 mm to 685 mm, designed to accommodate standard pallet sizes in Indian warehouses.