Closed Pallet Handling with Counterbalanced Stacker

A leading chemical process manufacturing industry constantly faces challenges in closed pallet handling with conventional stackers. Here’s how the AVCON counterbalanced stacker provided a simple yet innovative solution to solve vehicle loading, unloading, and pallet stacking applications and reduce recurring cost of forklift hiring charges.

A leading chemical industry specializes in lubricant processes and manufacturing for its domestic and international markets. With time-bound assignments and continuous inward and outward material movements, management continuously seeks ways to enhance operations and meet project timelines. However, like many manufacturing companies, they encountered challenges in optimizing their material handling processes.

Challenges

Customer’s premises were crowded with multiple outward assignments pending for loading inside the vehicle and inward material manually unloaded by workers, blocking the pathway for finished goods dispatch. Due to constraints of having a single loading/unloading point, deliveries were slowed down and dependent on expensive forklift hiring.

Safety Concerns: The existing material also posed safety risks to workers due to space constraints for forklift movement and human passage through the same bay.

The customer team, as a result, lacked real-time visibility into their dispatch schedules, making it difficult to track inventory, monitor equipment performance, and identify potential issues proactively.

Solution:

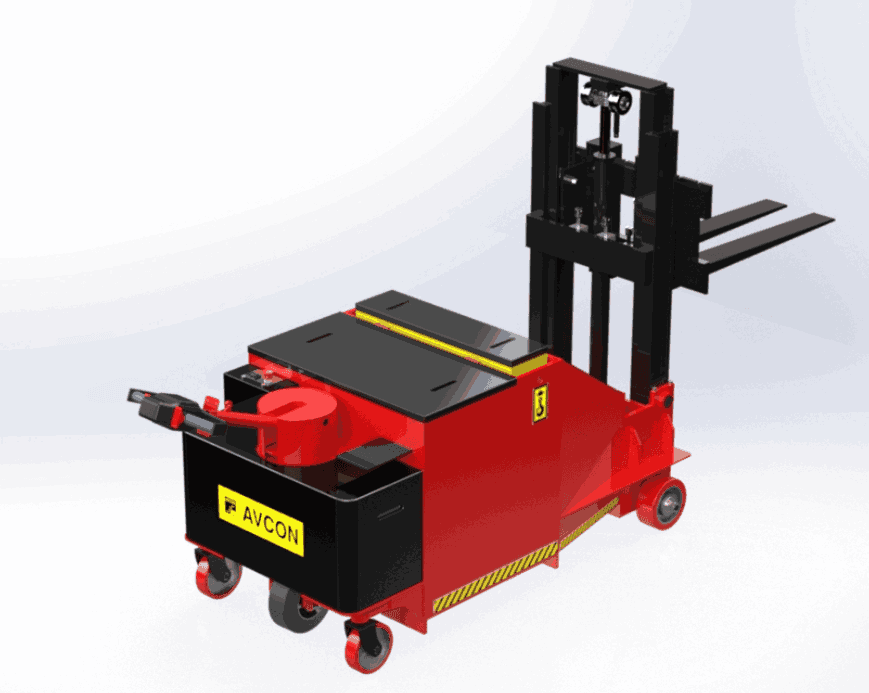

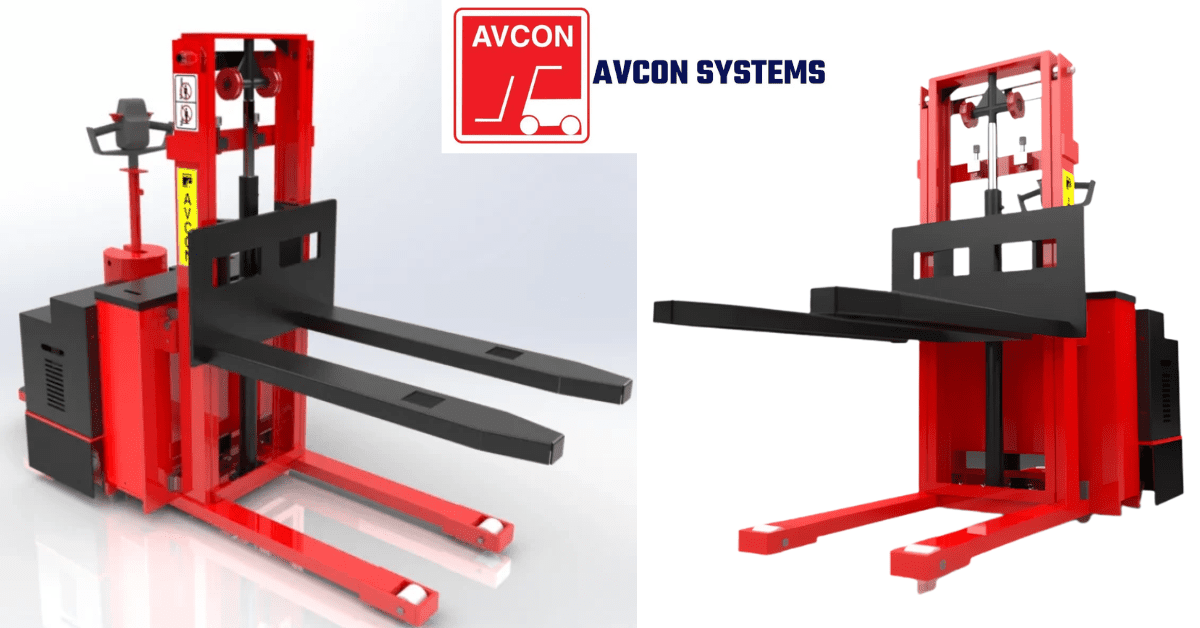

To address these challenges, the customer approached us to design and manufacture a counterbalanced stacker without front legs to handle all types of pallets available.

Customer invested in counterbalanced type design not only for their pallet stacking process for storage in heavy-duty racks, but also for pallet transportation and vehicle loading and unloading.

With the selection of a counterbalanced stacker for their application, the procedure not only became safer compared to manual loading also became easy for usage by every skillset worker with single-person operation. Due to the flexibility of lifting/lowering height, loading and unloading of all sizes of pallets is achieved using a stacker.

With a compact design and ease of operation for driving equipment usage has achieved maximum utilization of operational space.

Before

After

By adopting AVCON’s counterbalanced stacker, the company addressed these challenges, improved operational efficiency, and achieved significant cost savings, ensuring smooth material handling processes and safer work environments

By adopting AVCON’s counterbalanced stacker, the company addressed these challenges, improved operational efficiency, and achieved significant cost savings, ensuring smooth material handling processes and safer work environmentsResults:

With the incorporation of counterbalanced, the company achieved a 3 times faster turnaround time for drum pallet handling.

Due to the basic skill set required for operation and multiple safety driving features in the counterbalanced, fully electric stacker, we have eliminated multiple possibilities of accidents or unsafe loading patterns. Workers feel safe in handling of counterbalance stacker, and we have achieved zero accidents in handling drum pallets from the truck and loading the same on pallet racking.

Usage of counterbalanced stacker reduced the company’s cost of forklift hiring and labour to practically zero with no outsourced dependability for the factory material inward and outward process.

Implementation Process

The implementation began with a thorough assessment of the factory’s layout and workflow. Based on this analysis, AVCON developed a tailored counterbalanced stacker. Training sessions were conducted to ensure smooth adoption, focusing on safety protocols and efficient usage.

Key Benefits

- Enhanced Efficiency:

- Threefold improvement in turnaround time for drum pallet handling.

- Streamlined loading and unloading processes.

- Improved Safety:

- Elimination of unsafe loading patterns.

- Achieved zero accidents in pallet handling and material transportation.

- Cost Savings:

- Eliminated dependency on costly forklift rentals.

- Reduced labor costs associated with manual material handling.

- Operational Flexibility:

- Compact design ensured better space utilization.

- Adaptable to various pallet sizes and heavy-duty racking requirements.

Conclusion:

This lubricant manufacturing company successfully transformed its closed drum pallet material handling operations through the elementary adoption and process optimization. By addressing inefficiencies and enhancing safety, they were able to streamline their operations, increase productivity, and remain competitive in ever ever-evolving manufacturing sector.

This case study showcases the power of strategic decision-making and attitude to create a workplace that observes complete safety guidelines, resulting in business success.