#1. Premium Stackers Manufacturer

Stackers Manufacturer

Manufacturing Stackers Since 1984

Stackers Manufacturing

Avcon Systems, one of the oldest material handling solutions providers in the country, was established under the guidance of Mr. V.S. Sawarkar in 1984. Mr. V.S. Sawarkar, having more than 45 years in the material handling industry, founded Avcon in a very unpretentious manner, providing material handling solutions.

Our trusted solutions and commitment have made customers come back to us. Avcon has developed skills for helping our customers with the correct selection of equipment for optimum usage in a cost-effective manner. In the last 45 years, we have provided material handling solutions for practically every industrial application.

Industrial Stackers Manufacturer

Explore Our Comprehensive Lineup of Stackers Manufacturer

Our range of Electric

Stackers Manufacturer

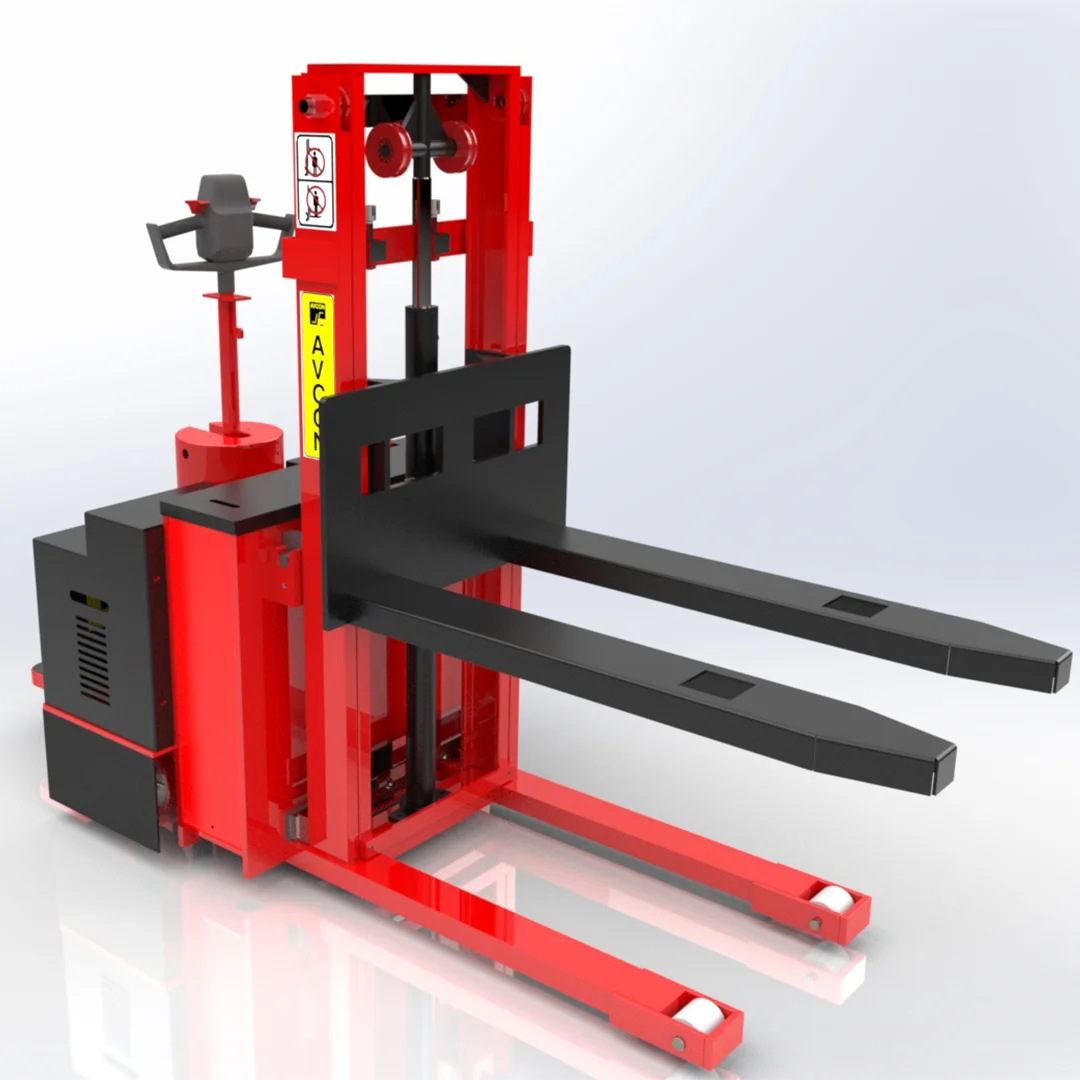

Battery Operated Fully Electric Stacker

Counter Balance Electric Stacker

Counterbalanced Semi Electric Stacker

Flameproof Semi Electric Stacker

Manual Hand Stacker

Mini Smart Forklifts

Platform Stacker

Portable Mini Stacker

Semi Electric Stacker

Semi Electric Stacker Straddle

Special Purpose Battery Operated Stacker

Stainless Steel

Stackers

Crafting Stackers Manufacturer Success

Stackers Manufacturer Success Story

A leading electrical vehicle chargers panels manufacturing industry constantly faces challenges in closed vehicle loading and unloading. Here’s how the AVCON stationary scissor lift provided a simple yet innovative solution to solve vehicle loading and unloading problems and reduce the recurring cost of crane hiring charges.

Safety Concerns: The existing material also posed safety risks to workers due to the manual handling of heavy loads and inadequate safety measures for storage.

The customer team as a result lacked real-time visibility into their dispatch schedules, making it difficult to track inventory, monitor equipment performance, and identify potential issues proactively.

The customer invested in a stationery pit-mounted scissor lift not only to serve as a loading unloading equipment but also to ingeniously place it at a location where it also serves as a goods transfer lift to their first-floor operations.

With the selection of scissor lift for their application the procedure not only became safer compared to manual loading but also became easy for usage by every skillset worker with single-person operation. Due to the flexibility of lifting / lowering height loading and unloading of all sizes of vehicles is achieved using a single scissor lift.

With a civil pit provided equipment matches the shop-floor level providing complete maximum utilization of operational space.

Due to the basic skill set required for operation and multiple safety features in the scissor lift we have eliminated multiple possibilities of accidents or unsafe loading patterns. Workers feel safe in handling of scissor lift and we have achieved zero accidents in handling loads from the truck and loading the same.

Usage of the scissor lift reduced the company’s cost of crane hiring and labor to practically zero with no outsourced dependability for factory material inward and outward processes.

This case study showcases the power of strategic decision-making and attitude to create a workplace observing complete safety guidelines resulting in business success.

Crafting Electric Stackers Manufacturer Success

Electric Stackers Manufacturer Success Story

A leading chemical process manufacturing company faced significant challenges in material handling, vehicle loading/unloading, and pallet stacking. By adopting AVCON’s counterbalanced stacker, they optimized their processes, enhanced safety, and reduced operational costs.

• Safety Risks: Space constraints for forklift movement increased safety concerns for workers and equipment.

• High Operational Costs: Frequent forklift hiring for material movement inflated costs and created dependency on external resources.

• Lack of Real-Time Visibility: Poor tracking of dispatch schedules and equipment performance hampered inventory and workflow management.

• Handling various pallet types for stacking, storage, and transportation.

• Safe and efficient one-person operation with basic skill requirements.

• Compact design for easy maneuvering in tight spaces.

Training sessions ensured smooth adoption and adherence to safety protocols.

• Improved Safety: Zero accidents reported due to elimination of unsafe loading practices.

• Cost Savings: Eliminated forklift hiring costs.

Electric Stackers Manufacturer

Hydraulic & Electric Stackers Manufacturer

Types of Stackers Manufacturer

Salient Features:

• Fully electric operation with ease of operation and faster pallet handling capacity.

• MOSFET-based controller for step-less control of the traction motor in acceleration and de-acceleration.

• Ergonomically designed handle for forward and reverse operation only at a 45-degree position with smooth steering operation.

• Battery discharge indicator for battery status.

• Easy maintenance access.

•Spring-loaded stand-on platform accessory for faster travel of the stacker.

• There are underlegs for free movement in pallet handling of all varieties.

•Adjustable forks with slide mechanisms for different pallet sizes.

• Tilt jack system for a mast for load stability in movement.

• MOSFET-based controller for step-less control of the traction motor in acceleration and de-acceleration.

• Ergonomically designed handle for forward and reverse operation only at a 45-degree position with smooth steering operation.

• Battery discharge indicator for battery status.

• Easy maintenance access.

• The absence of underlegs permits unrestricted pallet handling of all kinds.

• Modifiable forks with a sliding mechanism to accommodate various pallet widths.

• MOSFET-based controller for step-less control of the traction motor in acceleration and de-acceleration.

• A smooth steering experience with an ergonomic handle that is only intended for forward and reverse operation at a 45-degree angle.

• Battery discharge indicator for battery status.

• Simple maintenance access.

Optional Features:

• Remember to load the backrest for good stability.

• A flashing beacon.

• Fork extensions.

• Special dimensions for application suitability.

• In areas designated as flameproof, the use of stackers with flameproof power packs is permitted.

• All electrical items will be in flameproof enclosures.

• External cable supply required to connect stacker to the nearest supply point

• Available in MS / SS 304 Models.

• Suitable for Zone 1 and Zone 2 application areas.

• Non-sparking mechanical design for flammable areas.

• The compact design of the stacker makes it easy to move in less space.

• Dual pumping operation by the handle and foot pedal.

• Adjustable fork width for multiple pallet options.

• Release the lever in the handle for lowering.

• Special compact design for a narrow turning radius.

• STEP-LESS traction motor acceleration and deceleration controlled by a MOSFET-based controller.

• Only forward and reverse operations at a 45-degree angle are supported by an ergonomic handle that allows for smooth steering.

• Battery discharge indicator for battery status.

Optional Features:

• For excellent stability, load the backrest.

• Overhead Guard for Operator Protection.

• Flashing Beacon.

• Specific dimensions for the fork.

• Fork Extensions.

• Special dimensions for application suitability.

Salient Features

• Platform instead of forks for lifting material to the desired height.

• Dual pumping operation by the handle and foot pedal.

• Release lever in handle for lowering.

• Platform size: 1000 x 1000 (Can be customized)

• Motorized lifting and lowering mechanism for operator comfort and a faster stacking process.

• DC power pack for lifting mechanism.

•On-board battery and charger for supply to lifting motor.

• Push-button controls for lifting and lowering.

• Battery discharge indicator for battery status.

• Adjustable fork width for multiple pallet options.

• Motorized lifting and lowering mechanism for operator comfort and a faster stacking process.

• AC power pack for lifting mechanism.

• No charge is required.

• Adjustable fork width for multiple pallet options.

• Minimum Fork Clearance for easy entry.

• Adjustable fork width for multiple pallet sizes.

• Elimination of large-sized equipment like forklifts for medium-duty load handling.

• Easy for operation and maintenance.

• Motorized lifting/lowering mechanism for operator comfort and faster stacking process.

Special Purpose Categories:

• Clamp-Type Stacker.

• Boom Stacker.

• EDie Handling Stacker.

• Roll Handling Stacker.

• Four-Directional Stacker.

Salient Features :

• Fully electric operation for ease of operation and faster pallet handling capacity.

• MOSFET-based controller for step-less control of traction motor in acceleration and de-acceleration.

• Ergonomically designed handle for forward and reverse operation only at 45 degree position with smooth steering operation.

• Battery discharge indicator for battery status.

• Easy maintenance access.

• Spring-loaded stand-on platform accessory for faster travel of stacker.

Optional Features :

• Load the backrest to ensure the goods’ stability.

• Overhead Guard for Operator Protection.

• Flashing Beacon.

• Special fork dimensions.

• Fork Extensions.

• Special dimensions for application suitability.

• The manual pump is enclosed with an SS cover to avoid exposure.

• Matt finished the structure for the complete body.

• PU wheels for epoxy floor movement.

Specifically used for the pharmaceutical industry.

Why Choose Us

Why Choose Us

Video Gallery

Stackers Manufacturer for Each Industry

Our Products

For Multiple Industries!

Textile

Industry

Pharmaceutical

Industry

Rubber

Industry

E-Commerce

Industry

Logistics &

Warehousing

Paint Manufacturing Industry

Food Processing

Units

FMCG Group

Companies

Government Undertaking Organizations

Happy Client Says About Us

Jeffery Marshall

Amy Dasilva

Jeffery Marshall

Maria Speier

M. Bradbury

Amy Dasilva

Know all About Stackers Manufacturer

FAQs for Stackers Manufacturer

Yes, AVCON Systems' Manual Hand Stackers are specifically designed for operation in confined spaces. With their compact and ergonomic design, these Manual Stackers allow for easy maneuverability in narrow aisles and tight corners, making them perfect for warehouses and storage facilities with limited space. The stackers' precise steering and controlled lifting capabilities ensure efficient performance, even in restricted areas, demonstrating AVCON Systems' dedication to offering versatile and practical material handling solutions.

Avcon Systems is one of the oldest material-handling solution providers in the country. It was established under the guidance of Mr. V.S. Sawarkar in 1984.

Designed and Developed by Sigmaflux